DIGITAL PRINTING ON FABRIC:

Digital printing is made on white fabrics, or generally dyed in pastel tones, although in recent years it has begun to print even on black without too many problems, applying all the colors in succession, up to the reproduction of the original design. A variation of the printing in application is pigment printing, in which the vaporization is replaced by polymerization.

Digital printing on fabric is an act of printing digital files on fabric using inkjet printers.

There are mainly two successful methods of digital textile printing:

Sublimation digital printing:

this procedure is used for synthetic materials intended for indoor or outdoor environments. Inkjet web printers and odorless and washable inks are used to ensure bright, well-defined colors. This technique is used for printing on polyester or cotton / polyester mixed fabrics, or nylon, used in various sectors, from advertising signs to clothing.

Considered one of the most sophisticated printing techniques on fabric, sublimation allows for an imperceptible reproduction to the touch while maintaining the elastic, wash-resistant and perfectly breathable materials. It is therefore perfect for the production of sportswear, but also for the production of accessories such as scarves, ties and bags.

Direct digital printing (or ink-jet printing):

This fabric printing technique, also called DTG (Direct to Garment), is used for four-color printing on natural fabrics such as cotton or silk, and uses inks that are applied directly to the product. It is widely used in the clothing sector, for the production of t-shirts, polo shirts and other customized clothing items in cotton or other natural materials.

The technology behind both printers is inkjet.

Digital printing, once considered very expensive, has now become more accessible and common.

There are many advantages for digital printing, the main ones for which it is usually chosen are the following:

-You can only print the amount of fabric needed, without reaching exorbitant minimum orders

– Low cost start-up

– It needs less operating space

– High quality and precision printing, clear printing

– Combinations of unlimited colors

and more…

Some of the places where it can be used are: clothing, fabric banners, flags, tents, sails, car covers, etc.

Other methods of printing on fabric:

Silk-screen printing:

Screen printing is nowadays the most widely used printing technique in textile printing, both in continuous roll-to-roll and in garment printing. In practice, textile screen printing, using appropriately selected pigments and using water-based inks, is able to ensure extremely bright and solid prints on fabrics for domestic washing and with a soft coat, for which it is widely used by companies in the fashion and sportswear sector.

At the base of ink can be added a luminescent, reflective or phosphorescent powder according to the desired effect and, unlike then with digital printing, through screen printing it is possible to create very special and amazing effects

Transfer printing:

performed on synthetic fiber fabrics. It consists of transferring a decorative pattern from the paper to the fabric. The transfer takes place by coupling paper and fabric during the passage in the felt calender with a temperature of about 190-210 ° C. This is the condition for transforming the dyes present on the paper into gas (sublimation) which, during a time spent in the machine of about 18 – 25 seconds, are absorbed by the synthetic fibers of the fabric, penetrating and then printing it permanently.

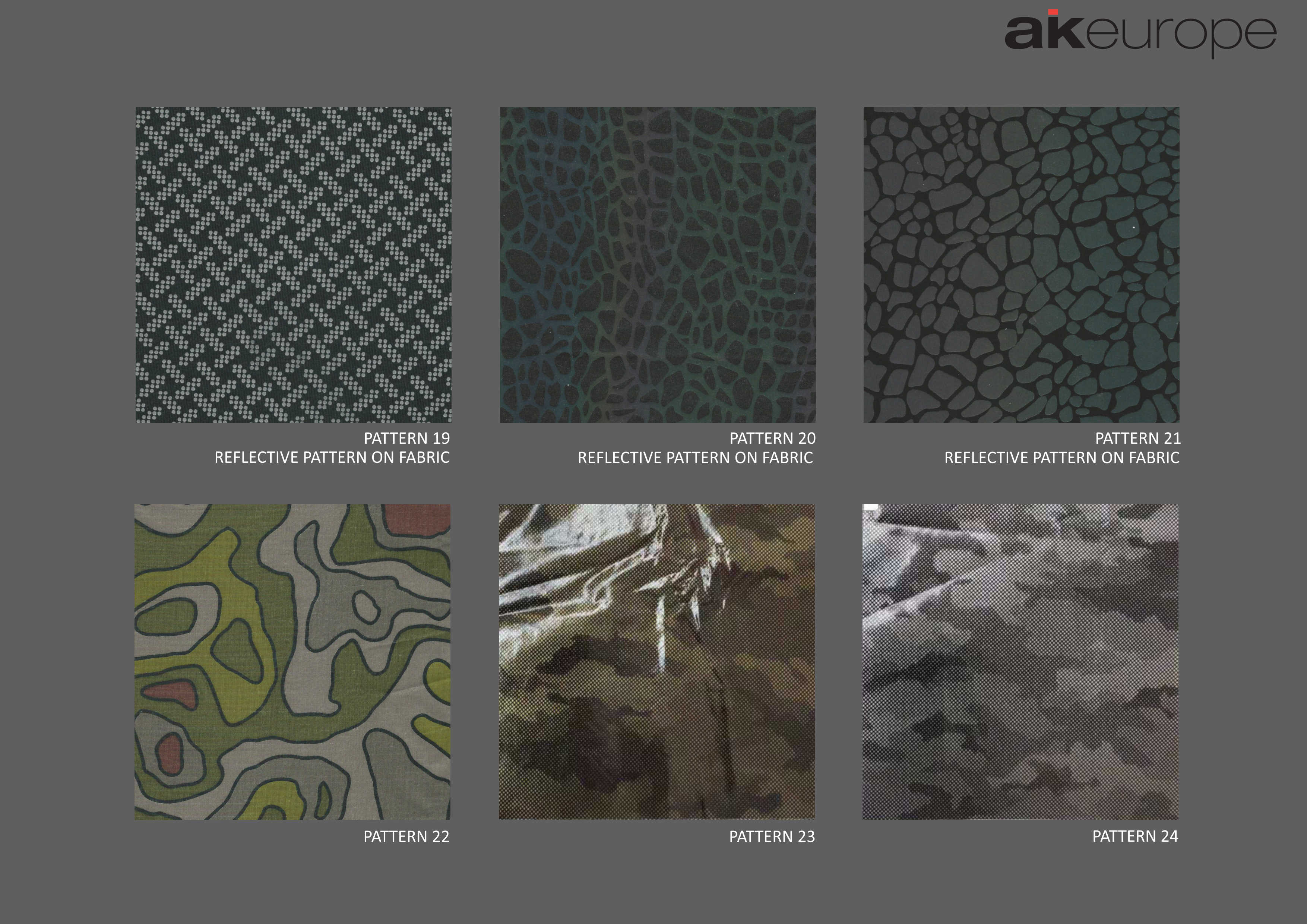

A reflective print can be created by inserting a sheet of reflective material between the grille and the fabric, with the same principle the print remains imprinted in the fabric.

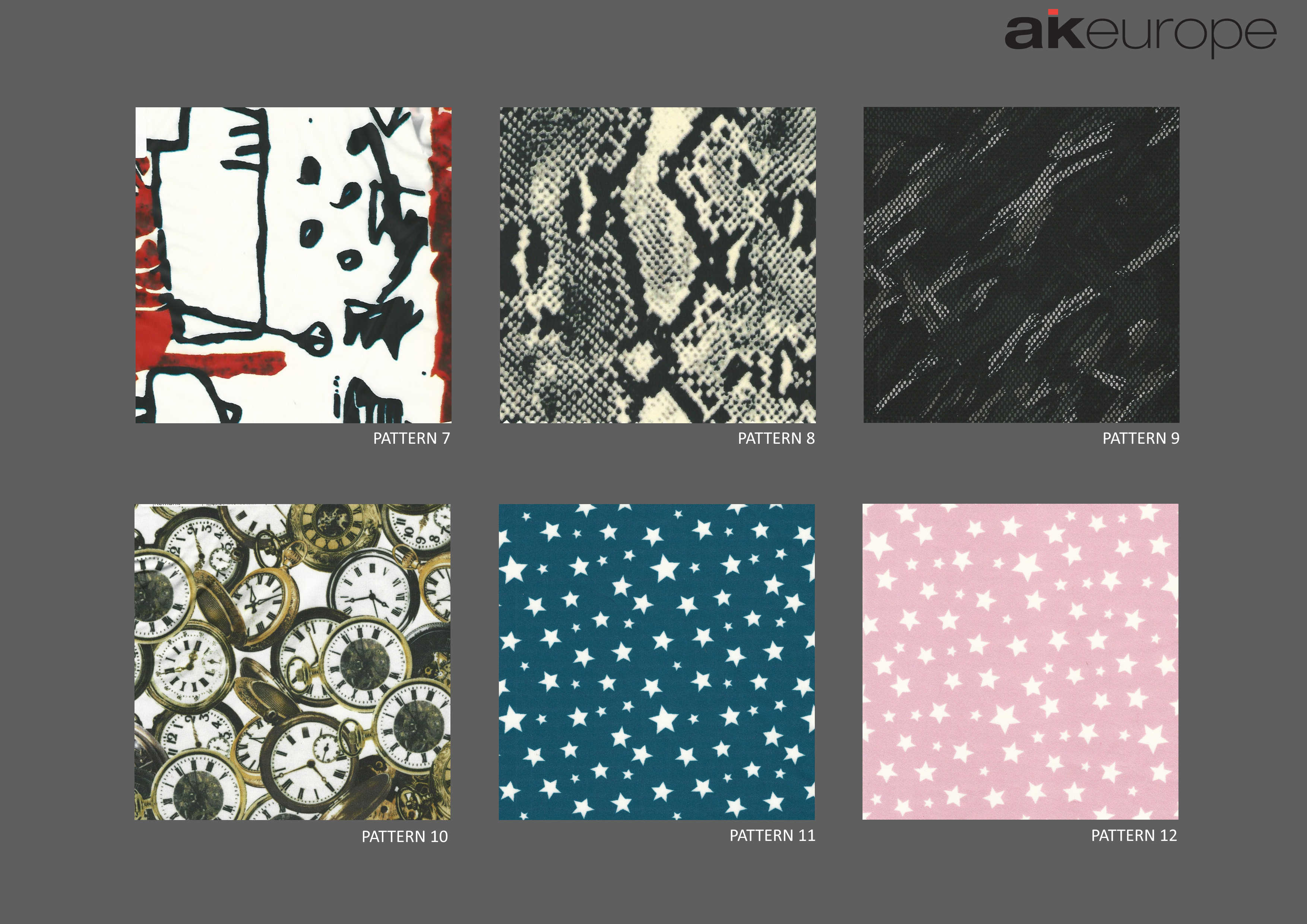

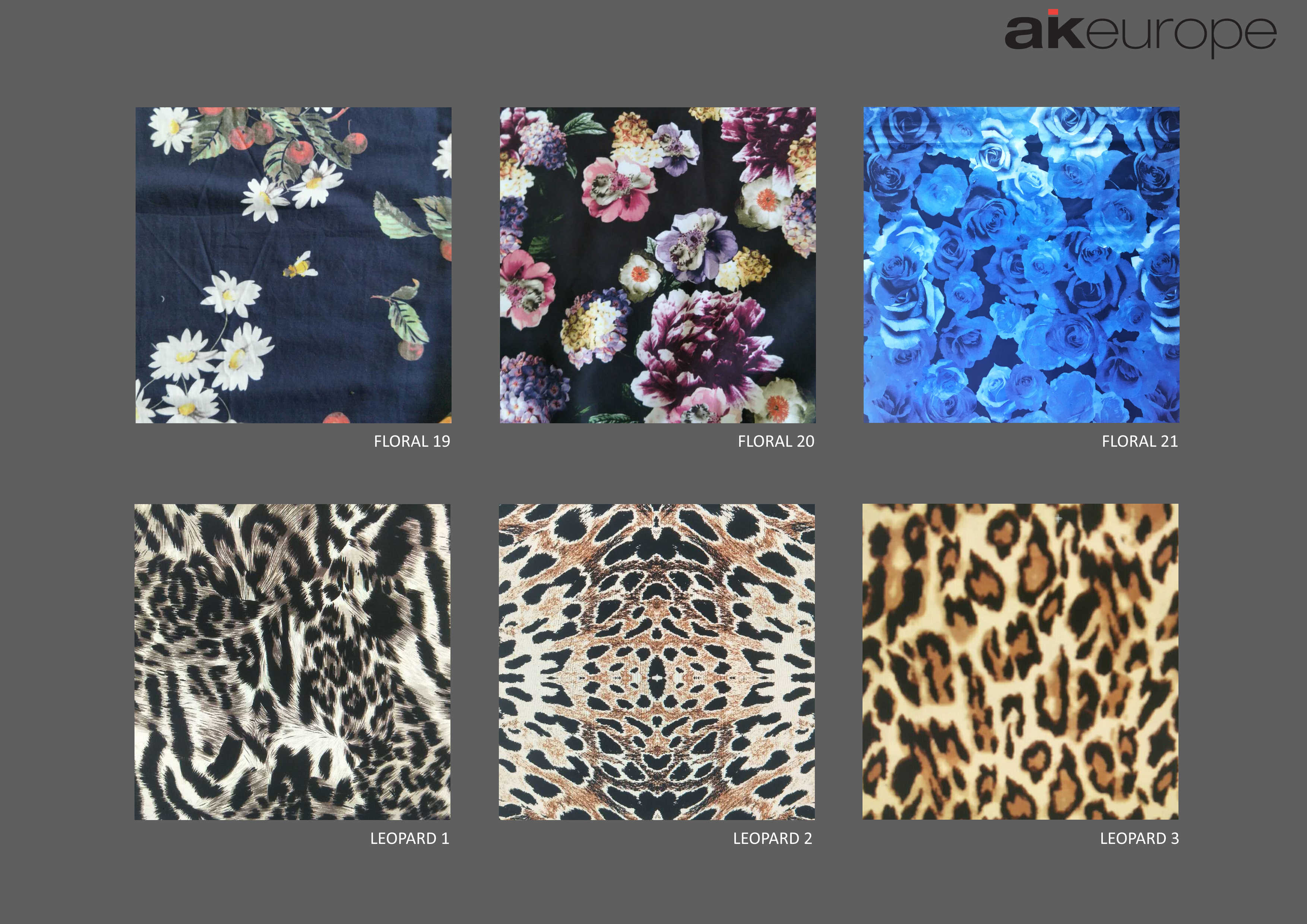

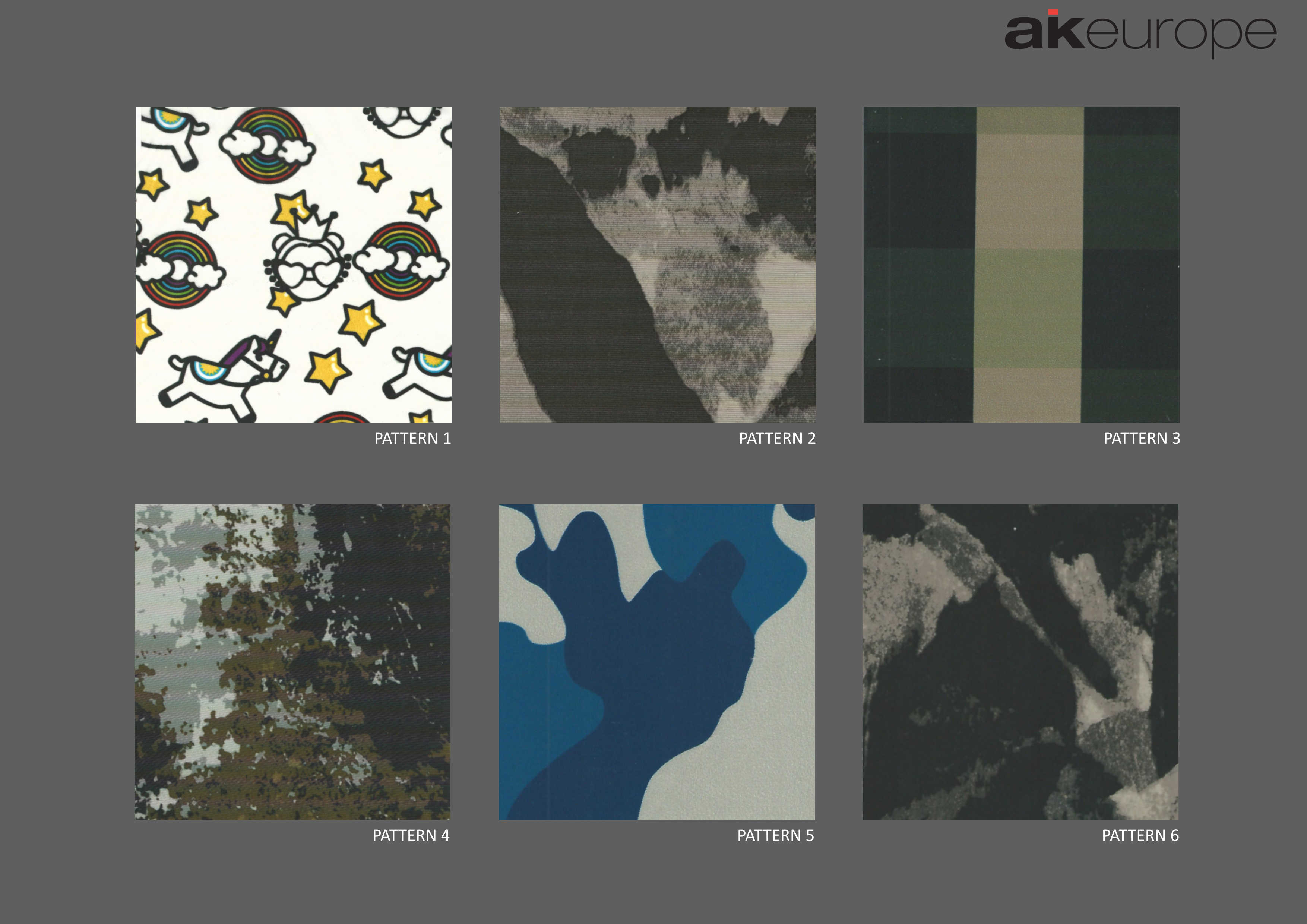

Here are some of the new proposals that AK EUROPE has selected for you: